Gravity free-fall style metal detector METRON 07 PowerLine

The highly sensitive METRON 07 PowerLine metal detector is installed in bulk conveying lines to detect metal particles. It can also be applied in pressure pipelines.

The METRON 07 PowerLine detector is easily integrated into existing installation thanks to its low overall height and compact dimensions.

The METRON 07 is a synonym for metal detectors with the highest detection accuracy and reliability.The detector coil has several layers of shielding and does not require a plastic sensor tube. This makes the detector immune to external electromagnetic interference and allows for extremely accurate metal detection.

This metal separator is made of stainless steel with an emphasis on hygienic design.There are no dead spots where the material could settle!

This detector is equipped with a first-rate AMD 07 control unit with a range of advanced features, such as a touch screen control panel, so its operation is simple and intuitive.It enables permanent monitoring of electronic and mechanical parts. The mesuNET system arranges for remote maintenance and network integration of the device. The unit is a part of the detector, but can also be placed outside the detector.

We supply this metal separator for pipes with a diameter of 50 – 300 mm as standard.

Principle advantages of a gravity free-fall style metal detector

- Metal detector with an opening for intallment into pressure pipeline transport apparatus. All metal particles are detected and it is both off-shell particles and the ones in the form of inclusions in the end product. Resistant against electromagnetic disturbance.

- Impressively easy operation.

- It conforms to quality requirements as per HACCP, IFS, BRC and SQF systems.

- Versatile and flexible device enabling easy adaptation to the individual requirements of the client.

The METRON 07 PowerLine gravity free-fall style metal detector is:

- Reliable – in process and detection

- Durable – in technology and performance

- Comfortable – in design and data management

Optional equipment

The QUICKTRON 07 RH HyQ Clean detectors can be supplied with a wide range of additional equipment:

- Signal units – beacon, buzzer, beacon with siren

- MesuSET – operation of detector via laptop

- MesuNET – network integration and remote maintenance

- Test etalons

Special design

Do you have special requirements for a metal detector design? The most common requirements include:

- Explosion proof versions

- Colour design according to requirements

- ALUTRON version – suppression of interference signals from metalized foils – Patent No. 4342826

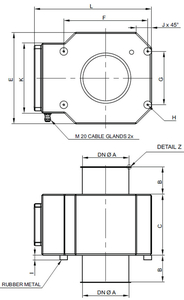

Dimensions

| A: (mm) | B: (mm) | C: (mm) | E: (mm) | F: (mm) | G: (mm) |

|---|---|---|---|---|---|

| 50 | 50 | 150 | 230 | 175 | 115 |

| 60 | 42 | 150 | 230 | 175 | 115 |

| 80 | 42 | 150 | 230 | 175 | 115 |

| 100 | 73 | 150 | 250 | 225 | 125 |

| 120 | 80 | 150 | 250 | 225 | 125 |

| 150 | 90 | 200 | 300 | 275 | 175 |

| 200 | 100 | 250 | 365 | 310 | 170 |

| 250 | 125 | 300 | 450 | 400 | 200 |

| 300 | 150 | 350 | 550 | 500 | 205 |

| H: (mm) | I: (mm) | J: (mm) | K: (mm) | L: (mm) | Weight (kg) |

|---|---|---|---|---|---|

| M6 | 15 | 45 | 230 | 274 | 16 |

| M6 | 15 | 45 | 230 | 274 | 19 |

| M6 | 15 | 45 | 230 | 289 | 22 |

| M6 | 15 | 50 | 250 | 339 | 25 |

| M6 | 15 | 50 | 250 | 339 | 28 |

| M6 | 15 | 50 | 230 | 384 | 30 |

| M8 | 30 | 88 | 230 | 451 | 35 |

| M8 | 30 | 115 | 230 | 534 | 40 |

| M8 | 30 | 160 | 230 | 634 | 45 |

We can supply units with different height, inside diameters, frames, etc. to meet your requirements.

We will ask you to specify the required modifications so that the offer can be elaborated exactly according to your requirement.

Metal free zone - MFZ

It is essential for the proper metal detector functioning that there are no fixed (e.g. conveyor structure, its covering) or moving metal parts (e.g. conveyor rollers) in the proximity of the detector’s aperture. Therefore, the MFZ is defined for each detector and it should not contain moving or fixed metals. The aperture of the metal detector is to be placed in the middle of this metal free zone. When you observe the MFZ when installing the detector, you will prevent false alarms and false detections and contribute to the correct detector operation.

Contact us – we will help you with the MFZ calculation for moving and fixed metals.

The great advantage of this metal detector is that a metal-free zone is not required.

Sensitivity of a metal detector

The detector's sensitivity depends on many parameters, such as the aperture dimensions (the lower is the aperture height, the higher is the detector sensitivity), the conveyor belt speed, the density of the product, its temperature and humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.

The sensitivity diagram of the METRON 05 D detector applies to LB 1,5 x LH

The METRON 07 PowerLine detector sensitivity diagram:

| Model | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|

| Sensitivity – steel ball dia. (mm) | 0,25 | 0,3 | 0,4 | 0,5 | 0,6 | 0,7 | 0,8 | 1,0 | 1,2 |

AMD 07 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Communication via Ethernet = unlimited flexibility

- Compact control unit

- Auto-balance including the suppression of interfering signals and automatic sensitivity calibration

- Dynamic auto-tracking – maximum sensitivity in operation

- Multi-filter system using digital filtration for maximum stability in harsh environments

- Self-monitoring system ensures that all important components function properly

- Narrow detection zone provides an accurate location of the metallic particle in the detection field allowing precise separation

- Easy intuitive operation – essential for detector operation

- 5.7" Color display

- Product storage memory backup – for up to 500 products

- Metal detector network and remote service - diagnostics, parameter change, SW update

- USB data media – USB data connection is a standard equipment to store data, carry out easy SW update, upload additional files etc.

Scope of delivery

The delivery of METRON 07 CI detectors includes:

- Detection head

- Control unit (= electronics mounted in a metal cabinet)

- Connecting cables

- Installation hardware

- User manual

- Power supply: 100 – 240 V AC, 50/60 Hz

- Power consumption: max. 50 W

- Type of protection: IP 66

- Min. working temperature: - 10 °C

- Max. working temperature: + 50 °C

- Relative air humidity: 0 – 95 % (without condensation)

- Feed pressure: max. +/- 0,5 bar

- Power cable: 1.8 m with plug