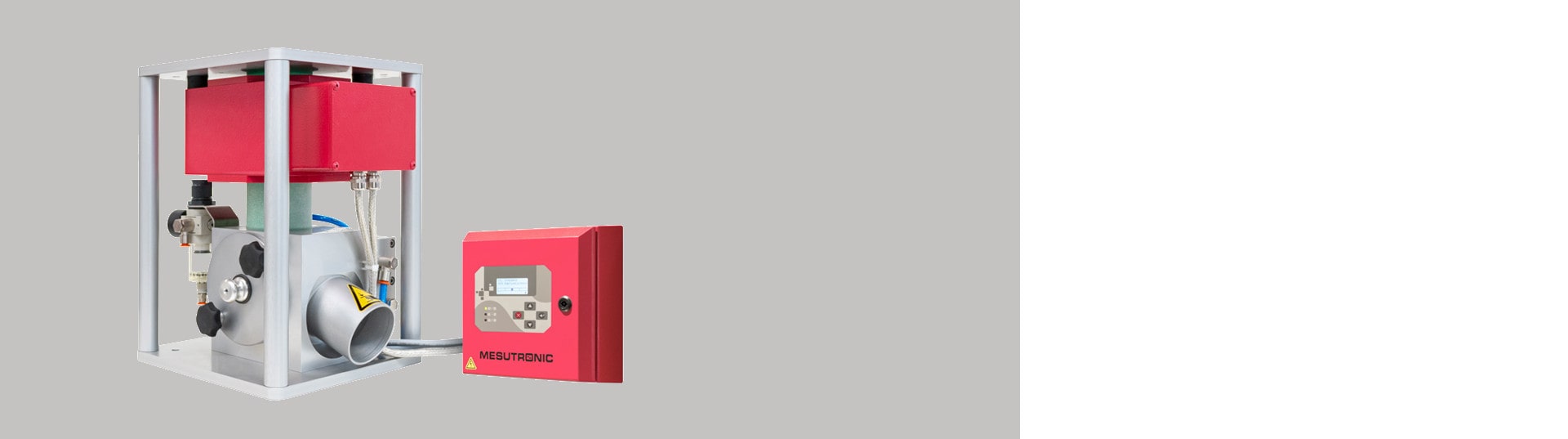

Gravity free-fall style metal detector PLASTRON 05 K for the plastics industry

The PLASTRON 05 K gravity metal detector is installed at injection molding machines and extruders and is used to detect metal particles in plastic materials. The detector is fully automatic, equipped with a high-speed reject flap, instantly diverting the detected foreign bodies and minimizing the loss of a good product.

The detector is made so that it can detect and reject metal particles even from a slowly flowing material (granulate, regrind, plastic flakes etc.). Both the detector and the reject flap have been specially developed for this application in the plastics industry.

The advantageous price and high sensitivity make the PLASTRON 05 K the most frequently used gravity style metal detector in the plastics industry.

Digital signal processing enables excellent detection results and the robust detector design contributes to its maximum lifetime.

The PLASTRON 05 K detector is easily integrated into an injection molding machine or an extruder due to its low height and compact dimensions.

We supply this detector with an inlet opening of 30 – 120 mm as standard.

The open frame detector design allows unlimited access to all its components. Maintenance is very easy, the whole device can be dismantled and cleaned without the use of tools.

If there is a higher presence of ferromagnetic particles in the processed material (e.g. when recycles plastic granules are used), we recommend to use one of the simple and efficient magnetic separators before the material gets to the detector. This will increase the protection of the subsequent technology (especially the injector nozzles) to the maximum. At the same time, the frequency of detections will be reduced (magnetic metals will be removed before they get to the detector and only the non-magnetic metals will have to be separated by the metal detector), what will also decrease the loss of the good material.

These separators can be purchased directly in our on-line store:

This detector is equipped with a high-performance AMD 05 control unit with a wide range of advanced functions. The unit is fitted out with a 5-line LCD display and controlled by 4 ergonomic buttons. Its operation is simple and intuitive.

Principle advantages of the gravity metal detector

- This detector was developed to separate metallic foreign bodies from plastic granulates, regrinds and powders.

- It is above all used at injection molding presses or extruders with a slow-flowing material columns.

- Thanks to the detector design there are achieved the best detection results, avoided blockades and minimized material losses.

The PLASTRON 05 gravity free-fall style metal detector is:

- Reliable – in process and detection

- Durable – in technology and performance

- Fast – in response and cleaning

Optional equipment

The PLASTRON 05 K detectors can be supplied with a wide range of additional equipment:

- Signal units – beacon, buzzer etc.

- Special length of connecting cables

- Extended self-monitoring - air pressure, diverter function

- Emptying the detector is performed by pressing the corresponding button

Special design

Do you have special requirements regarding the metal detector design? The most common requirements include:

- Version for abrasive materials

Dimensions

| Model | Weight (kg) |

|---|---|

| PLASTRON K 30 | 13 |

| PLASTRON K 40 | 13 |

| PLASTRON K 50 | 19 |

| PLASTRON K 60 | 19 |

| PLASTRON K 70 | 19 |

| PLASTRON K 100 | 35 |

| PLASTRON K 120 | 35 |

Metal free zone - MFZ

It is essential for the proper metal detector functioning that there are no fixed (e.g. conveyor structure, its covering) or moving metal parts (e.g. conveyor rollers) in the proximity of the detector’s aperture. Therefore, the MFZ is defined for each detector and it should not contain moving or fixed metals. The aperture of the metal detector is to be placed in the middle of this metal free zone. When you observe the MFZ when installing the detector, you will prevent false alarms and false detections and contribute to the correct detector operation.

Contact us – we will help you with the MFZ calculation for moving and fixed metals.

Sensitivity of a metal detector

The detector sensitivity depends on many parameters, such as the aperture diameter (the smaller the aperture, the higher the sensitivity), the material speed, the density of the product, its temperature, humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.17.03.2022

The PLASTRON 05 K sensitivity diagram:

| Model | Aperture diameter (mm) | Sensitivity (mm) | ||

|---|---|---|---|---|

| Fe | NonFe | SS | ||

| PLASTRON K 30 | 30 | 0,3 | 0,5 | 0,6 |

| PLASTRON K 40 | 40 | 0,4 | 0,6 | 0,8 |

| PLASTRON K 50 | 50 | 0,5 | 0,8 | 1,0 |

| PLASTRON K 60 | 60 | 0,6 | 1,0 | 1,2 |

| PLASTRON K 70 | 70 | 0,7 | 1,0 | 1,5 |

| PLASTRON K 100 | 100 | 1,0 | 1,5 | 2,0 |

| PLASTRON K 120 | 120 | 1,2 | 1,75 | 2,5 |

AMD 05 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and of the employed components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Control unit (of single board design) with built-in regulated power supply for reliable performance and ease of service

- Auto-balance including the suppression of interfering signals and automatic sensitivity calibration

- Multi-filter system using digital filtration for maximum stability in harsh environments

- Narrow detection zone provides an accurate location of the metallic particle in the detection field allowing precise separation

- Self-monitoring system ensures that all important components function properly

- Easy 4-button intuitive operation

- 5-line back-lit LCD display

- Product storage memory backup – for up to 500 products

Scope of delivery

The delivery of PLASTRON 05 K detector includes:

- Detection head

- Reject unit including pneumatic components such as air pressure regulator, etc.

- Control unit (= electronics mounted in a metal cabinet)

- Connecting cables

- Installation hardware

- User manual

- Power supply: 100 – 240 V AC, 50/60 Hz

- Power consumption: max. 50 W

- Type of electrical protection: IP 65

- Min. working temperature: - 10°C

- Max. working temperature: + 50°C

- Relative air humidity: 0 – 95 % (without condensation)

- Compressed air connection: 6 - 10 bar

- Compressed air consumption during the separation:

- PLASTRON K 30 – 70 = 6 l

- PLASTRON K 100 – 120 = 0 l

- The material speed at which metals can be reliably detected: 0.005 – 2.0 m/s

- Designed for the treatment of plastic granules (1 - 10 mm)

- Power cable: 1.8 m with a plug